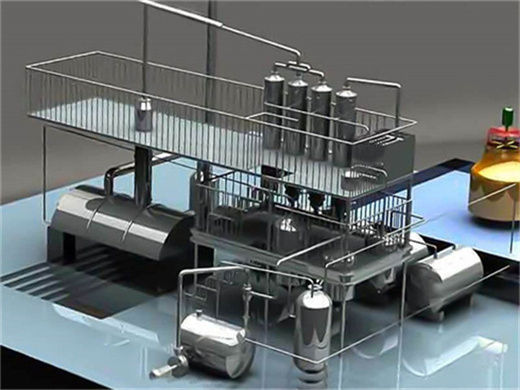

Palm Kernel Oil Expeller Machines Kenya MBL

- Usage:

- Palm oill Production Machinery, Palm oill Production Machinery

- Type:

- Cold & Hot Pressing Machine, Palm oill Production Machinery

- Automatic Grade:

- Automatic

- Production Capacity:

- 50TPD Palm oill Production Machinery

- Voltage:

- 380V

- Certification:

- ISO9001

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Material:

- Stainless and Carbonless Steel

- Raw Material:

- Palm,palm,Seasame,palm,Palm,etc

- Refining Process:

- Degumming,Deacidification,Deordorization,Decolorization,Dewaxing,etc

- Oil Standard:

- 1,2,3,4 Level

- Warranty:

- 1 Year

- Service:

- Engineer Abroad Erection

- Capacity:

- 5-500TPD

After pressing the crude palm oil you can get palm nuts, which can be used to extract the palm kernel oil. But before extract the palm kernel oil, the palm nuts must to be removed the shells firstly. For the large palm oil mill, there is a kernel recovery section called hydrocyclone equipment. But for the small and medium scale palm oil mill

A palm kernel oil factory available for sale.it is ready and functional.it has two oil extracting machines,two seed fryers,two 30Hp electric motors,a welding machine,two weighing scales,one cracking machine,100Kva generator,sixty 220 litres drums,electric oil press,three pumping machines,five metallic drums..every equipment is in good working

What machine can be used for cracking palm nut

Although, the traditional Kenya palm kernel shell separating machine is high efficiency and high separation rate, it is not economic for people who are interested in starting the palm kernel oil processing business with small capacity. Like Nigeria, the palm plantation is not as concentrated as in southeast Asia. So the local people want a

Palm Oil Pressing Machine For Sale In Kenya Palm

palm kernel oil extraction machine, palm kernel oil extraction machine Suppliers and Manufacturers at palmoilproduction. palmoilproduction offers 673 palm kernel oil extraction machine products. About 63% of these are Oil Pressers, 0% are Filter Press Equipment.

Biomass Active Marketing Palm Kernel Shell in Kenya

Palm Kernel Shell is the residual crushed shells from the extraction process of crude palm oil. It is fibrous material that can be easily handled in bulk directly from the product line to the end use. Today, PKS is considered to be an affordable and renewable source of biofuel.

Kenya Palm Kernel Expeller Mills Manufacturer

Muar Ban Lee Group is a world-leading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery. We provide "One Stop Service" in setting up Palm Kernel Crushing Plants from Plant Design and Fabrication to Installation and Commissionning. With our in-depth knowledge of the industry, our expertise

Palm Oil Mill Plant_Oil Machinery

The rude palm oil from oil press or solvent extraction plant, which should be refined for better edible oil. Palm oil mill capacity: 5-500T/H We are trustable palm oil mill manufacturer in China. We supply complete palm oil mill plants with capacities rages from 5-500T/H. The capacity is Normally capacity is less than 30t, directly pressing better.

Oil Palm Efb And Coconut Husk Long Fiber Extractor Machine

Palm and Coconut Shell Long Fiber Extracting Machine is used to extract fiber from material like oil palm, palm and coconut shell which contains lots of fiber.It turns pressed-EFB into long fiber 80-250mm in one step.The output fiber is used to make mattress, pulp and papers, shoe-pad, seat cushion etc.

Palm Kernels And Shells Separation Screening

A rotary separator for the dry mixture of palm kernel and shell. The results showed that the separation technique is viable for effective separation of the dry palm kernel and shell mixture.Also, a small fraction of the kernels are unexpectedly too small, and are discharged through the pre-cleaning screen; while some are entrapped with the shell, where shell...

Highly Efficient Palm Kernel Oil (PKO) Processing Machines

Detailed palm kernel oil extraction process by mechanical pressing method is as follow. Palm Kernel Oil (PKO) Processing Flow Chart. Palm Kernel and Shell Separation Palm Nut Cracker; Palm kernel and palm shell are obtained through the separation between kernel and shell. Normally, the shell can be used as fuel in the boiler system.

Palm Kernel Extraction : VIRIDIS Engineering Sdn Bhd

Palm Kernel Extraction. The residue from the press consists of a mixture of fibre and palm nuts. The nuts are separated from the fibre by hand in the small-scale operations. The sorted fibre is covered and allowed to heat, using its own internal exothermic reactions, for about two or three days.

Best Palm Kernel Expeller Machines for Sales

Generally, Palm Kernel Oil Extraction involves several steps, including palm kernel shell and nut separation, palm kernel selection, palm kernel cracking, palm kernel pressing, crude palm kernel oil filtration and palm kernel oil storage. In fact, palm kernel expeller is the most suitable oil extraction methods for palm kernel oil.