Auto Liquid Filling Machines Palm Oil Filling And Capping Machine In Nigeria | Palm Oil Production Line

- Usage:

- Palm Oil

- Type:

- Cold & Hot Pressing Machine, Palm oill Mill Machinery

- Automatic Grade:

- Automatic

- Production Capacity:

- 50TPD Palm oill Mill Machinery

- Voltage:

- 380V

- Power(W):

- Based On Palm oill Mill Machinery Capacity

- Dimension(L*W*H):

- Based On Palm oill Mill Machinery Capacity

- Weight:

- Based On Palm oill Mill Machinery Capacity

- Certification:

- ISO9001

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Raw Material:

- Vegetable Oil Suitable for Palm Kernel,Palm

- Pretreatment Process:

- Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Material:

- Stainless and Carbonless Steel

- Cooking Oil Machinery Process:

- Pre-treatment,Solvent Extraction,Refining

- Solvent Extraction Process:

- DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Service:

- Engineer Abroad Erection

- Refining Process:

- Degumming,Deacidification,Deordorization,Decoloration,etc

- Process Capacity:

- 30-500TPD

- Packing:

- Frame and Container

DYNAMIC ENTERPRISES(Ghana) Liquid filling machine is Automatic Volumetric Liquid Filling Machine. Suitable fill 1ml-5Lit

Every NEM Capping Machine is shipped ready to integrate into your line at your facility. Contact us today at 941.755.5550 for more information on any of our Capping Systems. Capping Systems may be also referred to as: Automatic Bottle Capping Ma

Palm Oil Filling And Capping Machine - Vietnam Liquid Packaging System

palm oil filling machine High-Speed and Fully Automated – Alibaba auto liquid filling machines palm oil filling and capping machine. Amazingly, palm oil filling machine are technically automated and with reinforced structures that enhance

Automatic Shampoo Filling And Capping Line - TopFillers

Home / Liquid Filling Line / Automatic Shampoo Filling And Capping Line Our automatic production lines (high speed) include 2 or more work positions: filling and capping, which are controlled by PLC. They are especially designed for the

Semi-Automatic Defoaming Corrosive Liquid Filling Machine - TopFillers - Cooking Top Liquid Filling Machines, Capping Machines, Labeling Machines

Features Our Bottom up filling machine is very suitable to fill rich foaming products, such as detergent, dishwasher, glass cleaner, disinfectant, lotion, etc. Quality assurance 1. Diving nozzle SVFA series machines are controlled by compressed

High Efficiency Manual Honey Filling Machine - TopFillers

Specifications high efficiency manual honey filling machine easy operation high accuracy filling speed and volume adjustable 316L steel Application Suitable for foods, daily chemicals, agrochemicals, medicine and other special chemicals. It is

Filling and Capping Machine - Npoat

Automatic filling capping machine (overflow filler) can do automatic bottle feeding, automatic liquid filling, automatic cap feeding, cap placing, cap screwing and automatic bottle out-feeding procedure, and the machine can be applied to round

Palm Oil Filling Machine, Palm Oil Bottling Machine - NPACK

Palm oil filling machine is improved on the basis of the original filling machine at home and abroad, which makes it easier to use, operate, precision error, installation adjustment, equipment cleaning, maintenance and so on. Palm oil filling

Best Liquid Filling Line For Sale - TopFillers

Automatic Capping Machine, Liquid Filling Line. 2-in-1 automatic bottle filling and capping machine for liquid 1.The material which contact directly with the oil is the SUS304 (GMP), made in Cooking. 2.The 3-in-1 is mainly used to food,

Awtomatikong Pagpuno ng palm oil at Capping Machine - Mga TopFillers

Ang aming Olive machine na pagpuno ng langis, nakakain na filler ng langis ay disenyo at paggawa ng espesyal para sa pagpuno ng bean oil, palm oil, palm oil at anumang iba pang mga uri ng nakakain na langis, ang kagamitan sa pagpuno ng langis

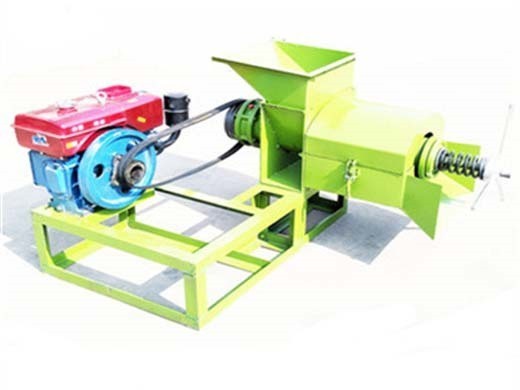

Palm oil mill process machinery - Palm oil extraction machine

Palm fruit sterilizing process: Palm fruits are very hard and so they have to first be softened before doing anything with them.Continuous sterilizer of palm oil mill is major section of palm oil mill process machinery.Palm oil mill sterilizer also called palm bunch sterilization machine.We are professional palm oil extraction machine manufacturer.We can product vertical sterilizer or

3tph palm oil pressing machine running video_Palm Oil Mill Video

This palm oil pressing machine can process palm fruit with capacity 3tph.This palm oil pressing machine belongs to automatic palm oil production line,which can save labors and easy aperation. The whole palm oil pressing machine includes palm fruit sterilizing machine ,palm fruit threshing machine , palm fruit digesting & pressing machine ,

- What are the advantages of palm oil press machine?

- Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. The fruits are then digested in the digester.

- How oil palm fruit is pressed?

- After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

- How a double screw & hydraulic oil press machine helps palm oil production?

- The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. The fruits are then digested in the digester. The digester is like a big blender and has a central shaft with arms that rotate and mesh up the fruit.

- How a palm oil press machine works?

- Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil press machine. Stirring and heating with steam to destroy the emulsified state forming from oil and water, where in the coagulation protein denaturation and to reduce the viscosity of the oil for further convenience of palm oil pressing process.