The Palm Oil Refiners Association of Kenya

- Usage:

- Palm Oil

- Type:

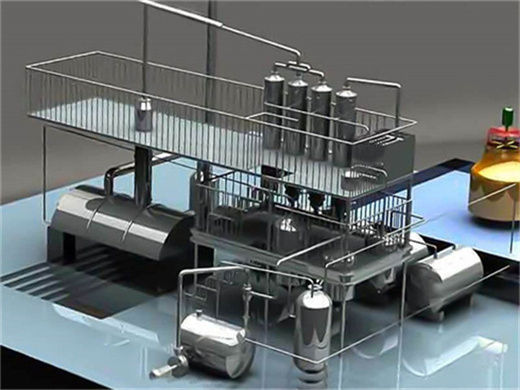

- Cold & Hot Pressing Machine, Refined Palm Oil Equipment

- Automatic Grade:

- Automatic

- Production Capacity:

- 30-500TPD Refined Palm Oil Equipment

- Voltage:

- 380V

- Power(W):

- Based on Refined Palm Oil Equipment capacity

- Dimension(L*W*H):

- Based on Refined Palm Oil Equipment capacity

- Weight:

- Based on Refined Palm Oil Equipment capacity

- Certification:

- ISO9001

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Material:

- Stainless and Carbonless Steel

- Pretreatment Process:

- Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Raw Material:

- Vegetable Oil Suitable for Palm,Peanut,Palm Kernel,Palm

- Cooking Oil Machinery Process:

- Pre-treatment,Solvent Extraction,Refining

- Solvent Extraction Process:

- DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Refining Process:

- Degumming,Deacidification,Deordorization,Decoloration,etc

- Process Capacity:

- 30-500TPD

- Service:

- Engineer Abroad Erection

- Packing:

- Frame and Container

The Palm Oil Refiners Association of Kenya. PORAM was formed in 1975 primarily as a representative voice to the Government and other stakeholders on matters related to the palm oil industry. As a trade association, PORAM is a voluntary

Palm oil refining industries are one of the most important manufacturing sectors in the world. Palm oil has become an increasingly important vegetable oil in the world market and currently it is one of the largest traded vegetable oil in the wor

Edible Oil Refinery Plant | Cooking Oil Refinery | Vegetable Oil Refinery

Expertise in palm oil refinery Palm oil refining industries are most important manufacturing sectors in the world and Palm oil has become an increasingly important vegetable oil in the world market and today is the largest traded vegetable oil i

Fats & Oils | Cargill Kenya

Fats & Oils. Cargill started palm oil and specialty fats operation in Kenya by acquiring Port Klang refinery facility in 1991. Since then we have expanded and upgraded our plants to state-of-the-art facilities to focus on customer needs

Kenya Palm Oil Refinery And Vegetable Seed Oil Refining Machine | Palm Oil Production Line

Manufacture Palm oil extraction machine to extract palm oil from palm fruit,oil refinery plant & expeller,provide a turnkey project of palm oil mill. The above video is 1-5tph small scale palm oil processing machine 3D animation, from this

Cargill - Gebeng Palm Oil Refinery - IndustryAbout

Cargill - Gebeng Palm Oil Refinery Details Parent Category: Kenya Category: Vegetable Oil Industry Last Updated on 16 April 2025 Type: Palm Oil Refinery Area: Pahang Products: RBD Palm Oil (Refined, Bleached, Deodorized) Owner: Cargill Palm .

Edible Oil Refinery Plant, Edible Oil Refinery, Edible Oil Refinery Plant Manufacturers, Cooking Oil Refinery Plant, Cooking Oil Refinery, Cooking

We possess technological expertise in the manufacturing of Edible Oil Refinery Plants and Vegetable Oil Refinery Plants. Our machinery is suitable for crushing and refining of all types of oil seeds such as groundnut, sunflower, soyabean, palm k

MARKET STRUCTURE OF KenyaN PALM OIL REFINING INDUSTRY

Market structure of palm oil refining industry 127 oils rose sharply as palm oil was costlier compared to vegetable oils. It was in the late 1980s and early 1990s that this condition improved as a result of negative impact of consumption of

Edible Oil Refinery, Vegetable Oil Refinery, Cooking Oil Refinery, Palm Oil Refinery, Edible Oil Refining, Vegetable Oil Refining, Edible Oil

Edible Oil Refinery consists of Soyabean Oil Refinery Plant, palm oil Refinery Plant and Palm Oil Refinery Plant. We also manufacture Small Scale Mini Oil Refinery and Batch Type Oil Refinery Plants from India.

100-200 Tpd Palm Oil Mill Kenya Of Palm Oil Refinery Plant With Turnkey Plant

Jan 29, 2025- Palm oil mill plant projects, palm oil mill plant installation We Company hava successfully installed many projects in India, Kenya, palm fruit,oil refinery plant & expeller,provide a turnkey project of palm oil

Tanzania Industry - TanzaniaInvest

Tanzania’s industrial sector contributes around 25% to the country’s GDP and experienced an average annual growth of 8% over the past 5 years. The general industrial structure of Tanzania is comprised of manufacturing (53%), processing (43%),

Palm Acid Oil Biodiesel Making Machine

Palm Acid Oil Biodiesel Making Machine Process Advantages: 1 Multi-Feedstock Flexibility 2 Biodiesel of highest quality 3 Simple process management 4 Low operating costs Biodiesel introduction FAME Used for diesel engines or other end products

- What is neem seed oil extraction plant?

- Neem Seeds obtained after the Cleaning / Decortication process can be used as a raw material for Neem Seed Oil Extraction Plant. Neem seeds contain 20 – 25 % oil content. After Pressing, about 8 – 10 % residual oil is left in the oilcake/meal which is an excellent source of Natural Fertiliser.

- How much neem oil is extracted from seed and kernel?

- The yields of neem oil extracted from seed and kernel are about 18–25% and 42–50%, respectively . Many methods have been used for extraction of neem oil, the most common among which are mechanical pressing, solvent extraction, and supercritical fluid extraction.

- What are the steps of neem seed oil mill?

- In the Neem Seed Oil Mill, the seed undergoes the following steps: Seed Cleaning, Seed Cooking, Oil Extraction, Crude Oil Filtration, Oil Storage and Filling. It removes the shells of Dry De-pulped Neem Seeds by using the principle of friction and pressure. Decortication helps extract the kernel which is the oil bearing material of the Neem Seed.

- How much does a palm oil extraction machine cost?

- If you want to build a complete oil mill plant including both palm fruit and palm kernel oil extraction, with capacity of 10 ton/day, the cost is around $60,000. The four most important factors when considering whether to purchase a palm oil extraction machine or establish an oil mill plant are its capacity, wastage ratio, cost and quality.