How much it will cost to set up a small palm kernel oil mill

- Usage:

- palm oill Mill mill

- Type:

- Cold & Hot Pressing Machine

- Automatic Grade:

- Automatic

- Production Capacity:

- 100%

- Voltage:

- 380V

- Power(W):

- according to capacity

- Dimension(L*W*H):

- according to capacity

- Weight:

- changed with the capacity

- Certification:

- CE and BV

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Product:

- palm oill Mill mill

- Capacity:

- 1-3000TPD

- Warranty:

- 12 months

- Raw material:

- oil seed

- Material of equipment:

- stainless steel and carbon steel

- Manufacturing experience:

- over 40 years experience in edible oil field

- type:

- palm oill Mill mill

- including:

- machines,installation,tech consulting after sales

- Automatic:

- Automatic

- operate:

- easy and safe

We will provide you the most complete information on palm kernel oil mill plant) Small palm kernel oil processing plant. If you want to know more information about How To Start High Yield Palm Kernel Oil Mill Plant in Nigeria? palm kernel oil production process,palm kernel oil refining process, palm kernel oil fracationation process. Visit http

A complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around. Note: The exact cost of starting a palm oil milling business in Nigeria depends on the capacity requirments, process design and equipment configuration.

How much it will cost to set up a palm oil mill plant

(4) Mature palm oil extraction technology : Company can supply palm oil processing machine rang from 300-500kg/h to 120tph. Users can choose palm oil processing machine according to the actural situation. Please don't hesitate, let's set up a palm oil mill plant and start your palm oil processing business in Papua New Guinea .

How to set up a new palm oil mill plant in Nigeria?__Industry...

As we all know, Nigeria, as one of the important palm planting countries, has a huge market and abundant raw materials. So more and more people want to know how to set up a new palm oil mill plant in Nigeria. Let me tell you some aspects that have to be considered when setting up a new palm oil mill plant in Nigeria. Palm oil press plant in Nigeria

How a Small Palm Oil Mill Plant is Set Up?

An interesting thing about the global palm oil market is that it needs mini and small palm oil mill plants in order for its marketing operations to be successful. Normally, a mini scale plant usually produces between 1-10 tonnes of palm oil daily while a small scale plant can process between 10-20 tonnes per day.

How much does it cost to set up a mini palm oil mill plant

How much it would cost to set up a mini palm oil mill plant in Nigeria? Generally, the total cost of establishing a palm oil mill plant will be decided by many factors, the palm oil mill processing plant cost is only one of the factors.

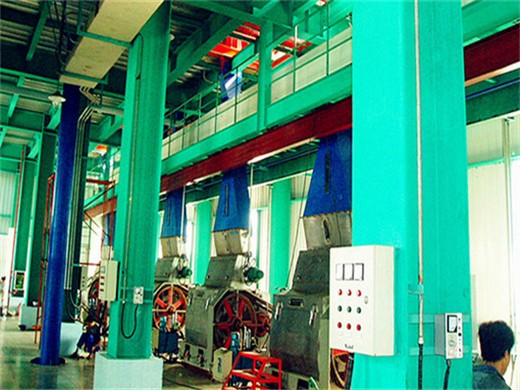

Set up Your Own Small Oil Pressing Production Line at Lowest Cost

Oil pressing and production can be done in oil mill plant. Usually there are three types of oil mill, small scale, medium scale and large scale. The conditions of starting a small scale oil pressing line is relatively simple and easy, especially for novice in oil processing industry. 5TPD Mini Cooking Oil Production Line

Small Palm Oil Mill Plant

The diesel-powered engines may be used to produce electricity to run different operation units in palm oil production plant. The number of operation units relies on the power needed to run them. (Related post: Setup A Palm Oil Mill in Nigeria) Turnkey Palm Oil Extraction Equipment. Process of Small Palm Oil Mill Plant

Palm Oil Mill Plant - Palm Oil Mill Machine Leading

Generally speaking, palm oil factory commonly be set in the palm orchard far away from the city, Power supply capacity is low. So, power-supply should be consider independently, build a captive power plant to meet the electricity needs of the palm oil factory which mainly determined by the electricity-consumption of equipment and auxiliary

1tph palm oil extraction plant project in Nigeria_palm oil

1tph palm oil extraction machines have produced in Doing Factory. These machines are designed by our engineers and manufactured by our manufacturing team in factory. If you also want to set up a small palm oil extraction plant, welcome you to our factory to visit! These 1tph palm oil extraction machines are loaded in the containers

Projects - Oil Mill Plant, Oil Refining Plant

We engaged in designing, installing and exporting a range of oil mill plants since 1950, and so far we have exported numerous complete oil plants like oil mill plant, oil extraction plant, oil refining plant both at home and abroad. Below are some of the oil mill plant projects we've already set up.

Cost To Set Up palm Oil Mill Plant

Unlike other oil mill plants, setting up a palm Oil Mill Plant is considered easier. Anybody familiar with the operation and with the required capital and machinery could have the palm oil mill up and running in a short period of time. The start-up capital required is considerably low when compared to that of starting other Mill plants.

- How does a palm oil mill work?

- A palm oil mill typically adopts a solvent-free process that uses steam and water for oil extraction. Interestingly, the process to extract the oil from the palm fruitlets has remained relatively unchanged for the past 50 years. Figure 1 shows the block flow diagram of a typical palm oil mill for the production of crude palm oil.

- How to prepare a palm oil mill plant for Operation?

- Operational readiness: Prepare the plant for full-scale operations by establishing standard operating procedures, quality control protocols, and safety measures. By following these general steps, one can establish a well-designed and properly equipped palm oil mill plant that is poised for efficient production and long-term success.

- How is palm oil processed?

- The fruit bunches are then transported to the processing facility for further processing. Extraction: The fruit bunches are sterilized, threshed, and pressed to extract the crude palm oil. This process involves a combination of mechanical and chemical processes and can vary depending on the specific equipment and techniques used.

- How to choose a palm oil mill plant?

- Palm oil mill plant layout design: The layout should optimize the flow of operations, facilitate maintenance and safety, and maximize space utilization. Palm oil milling equipment selection: finding a reliable palm oil mill machienry manufactuer or supplier to make sure the production capacity and efficiency.