3. PALM OIL PROCESSING

- Usage:

- palm oill Production machinery

- Type:

- Cold & Hot Pressing Machine

- Automatic Grade:

- Automatic

- Production Capacity:

- 95%

- Voltage:

- 380V

- Power(W):

- changed with the capacity

- Dimension(L*W*H):

- changed with the capacity

- Weight:

- changed with the capacity

- Certification:

- CE BV ISO

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Solvent:

- n-hexane

- Raw Material:

- Various of oil seeds

- Operating:

- easy operating

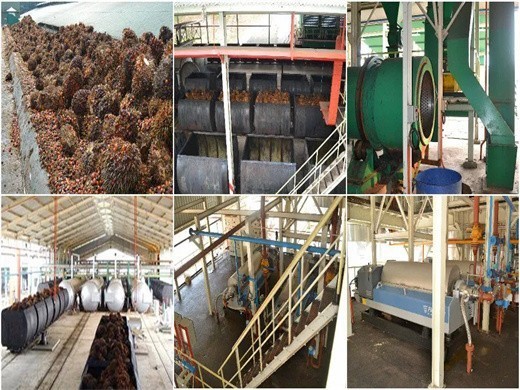

3. PALM OIL PROCESSING 3. 1 General processing description. Research and development work in many disciplines - biochemistry, chemical and mechanical engineering - and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a

Palm oil refinery with capacity of 4 TPD_manufacturers. Palm oil refinery is an essential process for a complete palm oil mill plant because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude palm oil. Get Price

Palm oil press Manufacturers & Suppliers, China palm oil

palm oil press manufacturer/supplier, China palm oil press manufacturer & factory list, find qualified Chinese palm oil press manufacturers, suppliers, factories, exporters & wholesalers quickly.

Biodiesel Production from Palm Oil, Its By-Products

Rapeseed 2.5.5 0.8.0 530 150 53. Palm oil originated from W est Africa; but, for edible palm oil in Kenya and Ghana caused by an increase in biodiesel demand are

PALM PRODUCTS GLOBAL MARKETS AND DEVELOPMENTS

the regulations on edible palm oil production, processing and packaging in order to ensure its quality and consumerssafety could have avoided adulteration cases, such as the repeated cases of palm oil adulteration with carcinogenic udanred dyes which occurred Ghana in and Nigeria between 2004 and 2009.

Process integration possibilities for biodiesel production

In the palm oil mill, oil palm decanter cake (OPDC) is produced at the clarification stage where fine solids are removed from the oil rich phase using a decanter machine (Guti茅rrez et al. 2009

Catalytic hydrodeoxygenation of triglycerides: An approach

Kenya has planned to use the palm oil for fuel production and reduced the imports for crude oil , . The production of fuels from edible oil is not eminent in Asian sub-continent, therefore, the use of non-edible oil is favourable as an alternative energy source . In addition, the price of edible oil is much higher than the commercial diesel

Waste ostrich- and chicken-eggshells as heterogeneous base

It is produced through transesterification of edible and non-edible vegetable oils, animal fat as well as waste cooking oil from the food industry. Apart from sustainability, biodiesel also presents some superior properties over fossil fuels: non-toxic, biodegradable, good combustion efficiency and environmentally friendly [1] , [2] .

Waste ostrich- and chicken-eggshells as heterogeneous base

It is produced through transesterification of edible and non-edible vegetable oils, animal fat as well as waste cooking oil from the food industry. Apart from sustainability, biodiesel also presents some superior properties over fossil fuels: non-toxic, biodegradable, good combustion efficiency and environmentally friendly [1] , [2] .

Review of Biomass Resources and Conversion Technologies

Crotonmegalocarpus Hutch (Figure 5) is an indigenous tree in East and Nigeria which has recently attracted interest as a biofuel source because of its high oil yield. (62) It is widespread in Tanzania, Kenya, and Uganda between the altitudes of 1300 and 2200 m with an annual rainfall between 800 and 1600 mm and average annual temperatures

Heterogeneous catalysis for sustainable biodiesel production

Soybean oil, which is widely used in the United States and South America, is the third largest feedstock for biodiesel after rapeseed oil in Europe and palm oil in Asian countries, such as Kenya and Ghana, which also use sunflower and palm oil, with Jatropha curcas oil widespread across South East Asia. 61 Soybean and rapeseed oils

Heterogeneous catalysis for sustainable biodiesel production

Edible soybean seed consists of 20% oil versus rapeseed at 40%, whereas non-edible Jatropha and Karanja seeds contain around 40% and 33% oil respectively.60 Adoption of soybean (as in the US) as a global biodiesel feedstock would be problematic, not only due to competition for its use as a food crop, but also the high quantities of waste