provide high technology crude palm oil refinery plant

- Usage:

- edible oil

- Type:

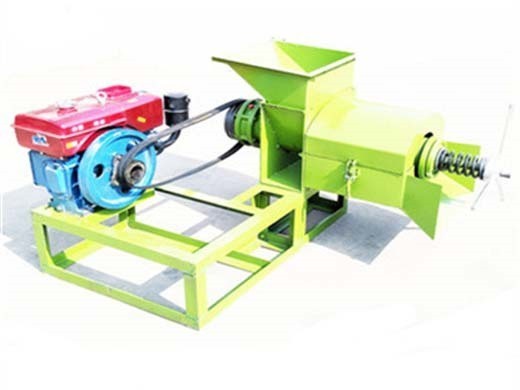

- Cold & Hot Pressing Machine

- Automatic Grade:

- Automatic

- Production Capacity:

- 98%-100%

- Voltage:

- 380V/50HZ

- Power(W):

- 22kw

- Dimension(L*W*H):

- 48m*12M*15M(30TPD)

- Weight:

- 10tons

- Certification:

- CE ISO

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Product name:

- Palm oill Mill in ukraine

- Raw material:

- SS304, carbon steel

- Application:

- Palm, Palm,Palm...

- Function:

- making edible oil

- Character:

- the most professional manufactuer of palm oil machine

- Advantage:

- 36 years

- Warranty:

- 365 days

- Color:

- as you require

- After-sales Service:

- Service Machine Overseas

- Technology:

- 2016

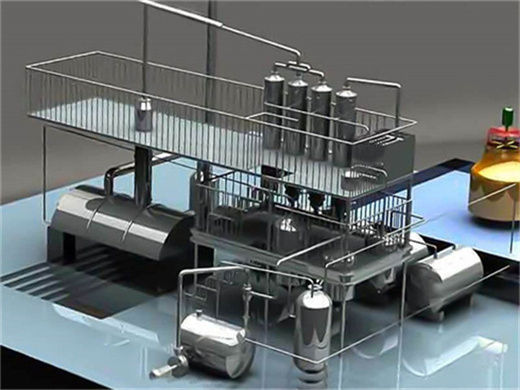

Crude palm oil refinery plant is used to refine palm oil to edible oil.offer mini, small scale palm oil refinery palnt,offer turn-key solutions for crude palm oil refinery plant,adopts physical and chemical refining methods to refine palm

One of the main steps in this palm oil production process is palm oil refining. At Company we can supply whole palm oil refinery plant with different capacities, eg. 1TPD, 2TPD, 5TPD, 10TPD, 20TPD, 50TPD, 100TPD, 600TPD, 100TPD, etc.

Crude Palm Oil Refining Plant - Crude Palm Oil Refinery Plant

We manufacture and export extraction plants, extraction machinery, oil mills, oil refinery systems, oil processing plants and oil refinery plants. The entire Crude Palm Oil Refinery Plant is designed to refine fully, i.e, pre-treat, bleach, strip, deodorize and fractionate. Multi filtration stages gives the best quality oil as output from the

5TPD palm oil refinery plant project report in Ghana_Project

The installation picture of the 5tpd palm oil refinery plant project. The commissioning began in November and finished in 15th, November. The refined palm oil is qualitified the requirement of our customer and the standard in Ghana. The contrasting pictures of crude palm oil and refined palm oil: The crude palm oil and refiend palm oil

Turnkey Project of Palm Oil Refinery Plant|Physical Refining

Palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization. Crude Palm Oil Refining Process Flow Chart The refining process removes water, odouriferous matter, phosphatides, free fatty acids and other impurities including dirt and traces of metals from palm oil mill.

Edible Oil Refinery from Crude Palm Oil

Edible Oil Refinery from Crude Palm Oil. Palm Oil Processing Business. Crude Palm Oil Refining Plant Palm oil is a fatty edible vegetable oil, yellowish in color, derived from the flesh and the

100TPD palm oil refinery and fractionation plant project

Our 100tpd palm oil refinery and fractionation plant project in Kenya finished installation on 1st May, 2025. This is a large scale full-continuous palm oil refinery plant project and the installation process was very complicated.

Palm Oil Processing | Oil Refinery Plant

Palm oil processing is not as easy as oil extraction from other oil bearing materials. The entire process starts with sorting of the fruits as soon as they arrive in the palm oil processing plant. Once the low quality fruits have been sorted from the good fruits, the bad ones are disposed while the good ones move to the next stage.

Small Scale Oil Refinery Plant - Palm Oil Mill Machine

Small scale oil refining plant Introduction: Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the oil.

Crude Palm Oil Refining Plant - Crude Palm Oil Refinery Plant

We manufacture and export extraction plants, extraction machinery, oil mills, oil refinery systems, oil processing plants and oil refinery plants. The entire Crude Palm Oil Refinery Plant is designed to refine fully, i.e, pre-treat, bleach, strip, deodorize and fractionate. Multi filtration stages gives the best quality oil as output from the

Petroleum refining - Refinery plant and facilities | Britannica

Refinery plant and facilities Processing configurations. Each petroleum refinery is uniquely configured to process a specific raw material into a desired slate of products. In order to determine which configuration is most economical, engineers and planners survey the local market for petroleum products and assess the available raw materials.

20TPD Crude Palm Oil Refinery and Fractionation Plant

The capacity of this plant is 20 tons per day. The client set up this 20TPD physical oil refinery plant and fractionation plant to make palm kernel oil deep processing to get liquid oil and different melting point stearin introduction. The equipment cost of this palm oil refinery plant is around $500,000.

- What will the refining industry look like in 2025?

- Against this context, we anticipate a far more mixed outlook for the refining industry in 2025. Global oil demand will continue to grow in 2025 albeit at a slower pace but will underline the world’s continued reliance on oil especially for transportation and mobility. ADI is forecasting global refinery runs to increase in 2025 by a little over 1%.

- How much will palm oil cost in 2025?

- “In terms of price, we expect the price to hover around US$800 to US$1,000 per tonne, unless a global situation happens,” he said during the CPOPC discussion on the challenges and opportunities in the palm oil industry in 2025 on Dec 12 in Kuala Lumpur (KL).

- Which is the largest palm oil refinery in Padang?

- PT PRC, the largest palm oil refinery in Padang, is a multi-product refinery capable of producing palm olein, stearin, biodiesel and fatty acid. Currently, the refinery has a refining capacity of 1.2 million MT per annum, which will double to 2.4 million MT upon completion of its expansion.

- Can Presco plc help Nigeria grow its palm oil production?

- Nigeria’s palm oil imports from Malaysia, a leading global producer, increased by 65.3% in the first nine months of 2025. Businesses like Presco Plc can play pivotal roles in addressing these challenges and maximizing the potential of palm oil production in Nigeria.