How to set up a new palm oil mill plant in Nigeria

- Usage:

- Palm Oil Refinery Machine, Palm Oil Refinery Machine

- Type:

- Cold & Hot Pressing Machine, 100TPD Palm Oil Refinery Machine

- Automatic Grade:

- Automatic

- Production Capacity:

- 100T Palm Oil Refinery Machine

- Voltage:

- 380V

- Certification:

- ISO9001

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Control system:

- Automatic

- Operation:

- Mechanized operation

- Matetial:

- Stainless Steel

- Raw Material:

- Palm,etc.

- Color:

- Siver

The size of your palm oil plantation decides the amount of fresh palm fruit bunches each day you can get, and which also determines the processing capacity and required machine in your palm oil mill plant. About the market, you need to do surveys and decide what final product you want to sell, crude palm oil or refined palm oil.

New Design Industry-leading Refined Bleached Deodorized Palm Oil Machine,Find Complete Details about New Design Industry-leading Refined Bleached Deodorized Palm Oil Machine,Palm Oil Production Process,Palm Oil Refining Machine,Palm Kernel Oil Processing Machine from Oil Pressers Supplier or Manufacturer-.

Palm Oil Processing Machine Price in Nigeria (Jul) 2025

Palm kernel shell oil press, red palm oil processing machine can be found at $4,746 to $75,548 approximately N1,648,830 to N26,819,540. Factory oil palm processing machines are at the prices of $1000 to $1,000,000. These machines are used mostly for large scale production of palm oil in oil

Manufacture Crude palm oil making machine,Low cost price

Crude palm oil making machine designed by our company can extract palm oil from palm fruit. This type of crude palm oil making machine process adopts mature and reasonable design, assuring high capacity of crude palm oil, low energy consumption, low cost and low environmental pollution.We are professional manufacturer of palm oil making machine,we can supply palm oil making machine

Palm oil refining line Palm oil extraction machine

We can get refined palm oil, which is edible at this step. 5.Fractionation: This is very important process in palm oil refining, But before this step, we have get edible palm oil, in another word, if not for special usage, this step could be cancled in palm oil refining. This is just a brief introduction about palm oil

Set up a Palm oil refinery plant with low cost, for sale

May 09, 2025· After extracting palm oil, the crude palm oil is sent to palm oil refinery plant for refining. Through several refining steps to remove free fatty acids, natural pigments and odors, crude palm oil becomes refined-bleached-deodoried palm oil (RBD PO). The refined palm oil is close to colorless and transparent in liquid form.

Small Scale Palm Oil Making Machine at Factory Price ABC

This Small Scale Palm Oil Processing Equipment is the best choice for start Palm Oil Production Business.They have many outstanding features: Energy Saving Reduce electric power by 40% for the same output. If calculated as saving 6 KWH per hour on average, the daily production can save about $4 in electricity bills.

refined palm fruit oil presser with competive prices

Price List Of 5t,10t,20t,100tph Palm Fruit Oil Presser. Price List Of 5t,10t,20t,100tph Palm Fruit Oil Presser Machine,Palm Oil Press,Price List Of 5t,10t,20t,100tph Palm Fruit Oil Presser Machine,Palm Oil Press,Palm Oil Press,Palm Fruit Oil Presser,Oil Presser Machine from Oil Pressers Supplier or Manufacturer-.

BEST Oil Manufacturing Plant, Palm Oil Making Machines

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Palm oil mill process Palm oil extraction machine

5. Palm oil mill process of oil clarifying: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment.Oil by centrifugal separation and through vacuum drying pumped into the storage tank for storing; oil sediment by

Professional manufacturer palm oil refining plant

100% Authentic. Oil Expeller, Oil Press and Oil Refinery Machine Supplier Professional manufacturer palm oil refining plant Highest Quality. Certified 21.772 Weight Supplier. TIMKEN Manufacturer Name

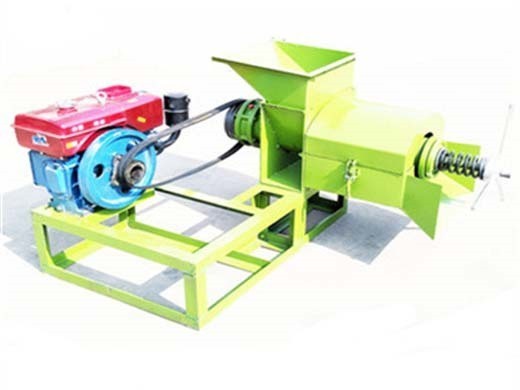

Newest design YL-130 small palm oil press machine

Manufacturing Newest design YL-130 small palm oil press machine,We are professional manufacturer in palm oil press machine industry. Our engineers focus on new technology researching of palm oil press machine all the time. We have designed a new small palm oil press machine

- What is a palm oil press machine?

- Reliable palm oil press machine with simple operation, gaining a good reputation in Africa and South America. The main products of the palm fruit plant are palm kernels and crude palm oil, and the processing capacity is about 60 to 100 tons of palm fruit bunches per hour.

- What is palm oil refining process?

- The refining process includes degumming, deacidification, decolorization and deodorization, obtaining high quality refined palm oil. Palm oil fractionation equipment can separate palm oil into soft fat and hard fat by controlling the cooling and crystallization process of palm oil.

- What is 3D customized palm oil milling process?

- 3D Customized Palm Oil Milling Process Flow Chart Planting and Cultivation: In this stage, palm trees are planted and cultivated to produce fresh fruit bunches, which will be harvested and processed into palm oil.

- What is palm oil milling?

- Palm oil milling is the process of obtaining edible palm oil from ripe palm fruits. The milling the crude palm oil. The extracted oil is further purified and dried for storage and export. manual/traditional method and the mechanized/ modern method. While the former is employed by involved in the palm oil milling process.