Preparation of Medicinal Plants: Basic Extraction

- Usage:

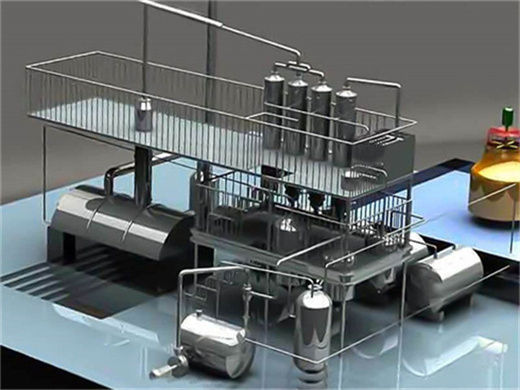

- Palm Oil, Refine crude oil of Farm machienry

- Type:

- Palm oill Production plant, Palm oill Production plant

- Automatic Grade:

- Automatic

- Production Capacity:

- 100%

- Voltage:

- 220/380/400 Voltage

- Power(W):

- 162kw

- Dimension(L*W*H):

- 16*8*15

- Weight:

- 186022kg

- Certification:

- CE&BV

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Origin:

- China

- Processing material:

- Crude edible oil/palm oil/Palm oil/corn oil/Palm oil

- Processing capacity:

- 1 Ton to 600 Ton per day

- Final product:

- High quality edible cooking oil

- Certificate:

- CE&BV&TUV

- Color:

- According to facility usage

- After-sale service:

- 1 year warranty

Consequently, when the level of solvent in the extraction chamber reaches the top of the siphon, the solvent and the extracted plant material flow back to the flask.[1,2,3,4,11,17,18] The entire process continues repeatedly until the drug is completely extracted, a point when a solvent flowing from extraction chamber does not leave any residue

SOLVENT EXTRACTION. This method employs food grade solvents like hexane and ethanol to isolate essential oils from plant material. It is best suited for plant materials that yield low amounts of essential oil, that are largely resinous, or that are delicate aromatics unable to withstand the pressure and distress of steam distillation.

Solvent Extraction Plant, Tea Extraction Plant, Spice

The oil extraction yield of 90% was achieved using n-hexane as an organic solvent at the optimized extraction conditions. The optimized parameters for oil extraction include the oil to solvent ratio of 1:1, mixing speed of 500 rpm, mixing time of 25 min, and pH of 10.

Solvent Extraction Method for Edible Oil Processing

Another promising green solvent such as switchable solvent has showed potential for oil extraction from soy bean flakes . In addition, super critical fluid, deep eutectic solvents, natural deep eutectic solvents and supramolecular solvents are gaining wide interest and there is a need to study their applicability in oil extraction [ 11,20 ].

Base Oil Solvent Extraction Refining Plant VMETS

Solvent Extraction. Solvent Extraction is the term for the removal of most of the ring structures and aromatics (weak, undesirable components) of oil distillates by liquid extraction. Common and suitable solvents are phenol, furfural and sulphur dioxide. Furfural is used extensively as the extractant for the refining of paraffinic oils.

SOLVENT EXTRACTION Oils and Plants

SOLVENT EXTRACTION. Solvent extraction is used to extract Essential Oils from plants that cannot withstand the high heat used in steam distillation. Very delicate aromatics, Jasmine, Linden Blossom, etc can not survive the process of distillation.To capture their magical aromas, a process of solvent extraction is used.

edible oil solvent plant extraction

Edible Oil Extraction Solvent Plant Soybean Extraction Plant 30tpd Soybean Cake Edible Oil Extraction Solvent Toasted Machine Plant Equipment Mill Project In Kenya. $45,000.00-$50,000.00/ Set. 1 Set(Min. Order) Get Price

Palm and Palm Kernel Oil Production and Processing

Jan 01, 2012· Palm kernel solvent extraction initially was popular in the 1980s, but the majority of these solvent extraction plants have ceased operations due to high solvent loss and concerns about safety issues. To date, only one palm kernel solvent extraction plant is still operating in Kenya.

Palm Kernel Oil Solvent Extraction Plant,Extraction Machine

Solvent Extraction Station of Oil Mill Plant. Solvent Extraction Workshop of Oil Mill Project in Zambia. Solvent Extraction Plant Onsite Installing. Solvent Extraction Oil Mill Plant Construction. In the old days, all oil mills or factories adopted mechanical extraction method by use of screw press for kernel oil recovery. However, with the

Solvent Selection in Extraction of Essential Oil

Solvent extraction has been widely used to extract bioactive components from plants (Musa et al., 2011). Besides, the study of the solvent effects on the extraction of active components from herbs is very important for the screening and selection of the solvent for the extraction, fractionation and purification steps in the herbal processing.

(PDF) Heat exchanger analysis to reduce hexane loss

The study is carried out in a leading palm oil factory in Kenya. At present solvent extraction plant are facing problem of high hexane loss, average 9.5 litre/metric ton (ltr/mt). To reduce the

Solvent Extraction Plant Manufacturers Solvent

The extraction plant comprises of extraction De-solventizing Toaster, a Distillation System and a Solvent Recovery System. The extractor enables removal of the solvent from the meal, toasts the meal to maintain inherent nutrition, and stabilizes its moisture as well as temperature.