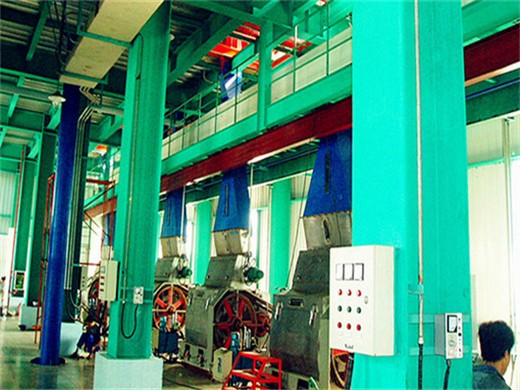

PALM OIL EXTRACTION USING ENZYME MIXTURE

- Usage:

- Palm Oil

- Type:

- professional palm kernel oil refined machine

- Automatic Grade:

- Automatic

- Production Capacity:

- 1-3000T/D

- Voltage:

- 220V ,380V

- Power(W):

- According to your machine capacity

- Dimension(L*W*H):

- According to your machine capacity

- Weight:

- According to the your machine capacity

- Certification:

- ISO9001 & CE

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Product name:

- Professional palm kernel oil refined machine

- Transparency:

- 500C transparent

- Smell,taste:

- Smell and taste is good

- Color(133.47mm dispoable cuvettes):

- less thanY30R3.0

- Moisture and volatile matter%:

- less than0.05

- Wastes%:

- less than0.05

- Melting point0C:

- 33-39

- Acid value mgKOH/g:

- less than1.0

- Peroxide value mmol/L:

- less than 10

- Warranty:

- 12 Months

Pakistan oil palm has the highest productivity amongst cultivated oleaginous crops. Species can constitute a single crop capable to fulfill the growing global demand for vegetable oils, which is estimated to reach 240 million tons by 2050. Two types of vegetable oil are extracted from the palm fruit on commercial scale. The crude palm oil and kernel palm oil have different fatty acid profiles

Oil palm (Elaeis guineensis) trunk chips were processed by steam explosion under different steam conditions, followed by alkaline extraction and fermentation to produce efficient lignocellulosic ethanol as sustainable alternative energy resource.The optimum condition of steam explosion was attained at 210 °C for 4 min (α-cellulose: 58.83% and lignin: 27.12%).

Eco-friendly extraction and characterization of cellulose

Alkaline hydrogen peroxide (AHP) as a pretreatment effectively enhances the increasing enzymatic digestibility of oil palm trunk (OPT) for conversion to biofuels and bioproducts in the biorefinery processes. The effect of hydrogen peroxide concentration (1–5%), temperature (50–90 °C), and time (30–90 min) were studied to find out the optimum condition for the removal of lignin. The

Special Issue "Green Separation and Extraction Processes"

Interesterification reaction of palm oil and ethyl acetate for the synthesis of biodiesel was performed in a small-scale fixed-bed reactor. The reactor was packed with ion-exchange resin (RCP160M), which was used as catalyst for this work. The important factors affecting biodiesel content including reaction temperature, mass flow rate of reactants, and ethyl acetate-to-oil molar ratio were

Purification, identification, characterization

There is yet any study on the extraction of ferulic acid from oil palm by microwave assisted DES extraction. Due to the high lignin and cellulose content (13–25% and 43–65% respectively) in the palm pressed fibre, the DES is believed to better penetrate into the fibre matrixes in higher efficiency and ease for the extraction of ferulic acid

Recent development and challenges in extraction

The hot compressed water extraction (HCWE) is an alternative to the screw press extraction in the SLE of palm oil and ß-carotene from palm oil mesocarp (Sharizan, Azian, Yoshiyuki, Kamal, & Yunus, 2025). HCWE is a green process that utilizes water solely as the extractant under the conditions of high pressure and high temperature.

Enzymes for Improving Oil Yield in Palm Oil Extraction

start palm oil extraction using enzymes has rendered good results Success and positive results at every step, it has been a morale booster for AETL to further expand its work in the area of palm oil extraction AETL is working in close association with palm oil producers in Ghana, Kenya, Ghana and Thailand 2006 2007- 2009 2010 2025 2025

Destabilization of Emulsion Formed During Aqueous

Combination of Span 20 and pH-assisted walnut oil extraction during aqueous extraction process ppm to the palm oil emulsion in water resulted in a dramatic decrease peroxide values formation

(PDF) Biomethanation of Palm Oil Mill Effluent (POME)

Palm oil mill effluent (POME) with average chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of 70,000 and 30,000 mg/L, respectively, can cause serious environmental hazard if discharged untreated. There are conventional palm oil mill

Effect of Different Solvent and Ratio Towards Microalgae

Based on Figure 3, 8% is the highest total oil extraction yield obtained from combination of chloroform and ethanol with a ratio (1:2). Approximately, 6% total oil extraction yield obtained using chloroform and hexane with a ratio (1:1).Whereas 5% oil extraction yield was obtained using chloroform and hexane with a ratio (1:2).

Development and Scale-up of Aqueous Surfactant

When 1.2 wt% Tween 20 aqueous solution was used for oil extraction at pH 10.0, the highest free oil yield was achieved at 76.1 %, which was similar to the oil recovery of using proteases as a

Combination of fatty acids extraction and enzymatic

The production of biodiesel using residual oil from palm oil mill effluent and crude lipase from oil palm fruit as an alternative substrate and catalyst Fuel,195 ( 2025 ),pp. 82 87,10.1016/j.fuel.2025.01.049

- How span 20 is used to demulsify walnut oil?

- Demulsification mechanism using Span 20 at acidic pH during SAAE was discovered. Highest walnut oil yield (90.74%) was obtained at sugar solution of 1 mol/L, solvent-to-sample ratio of 4:1, and extraction temperature of 85 °C, extraction time of 60 min, 1.9 g/100 g Span 20, and pH 6.0.

- How does span 20 affect extraction yield?

- However, the effect of Span 20 on extraction yield illustrate a key difference in extraction mechanisms ( Fig. 4 d), effectively destabilizing the emulsion formed and increasing yield from 60.56% to 90.74% during extraction of walnut. Span 20 possesses lower molecular mass and diffuses rapidly to the interface than protein.

- Does span 20 destabilize the emulsion?

- The oil yields of AEP, SAAE and SSAE were 44.7%, 55.3% and 91.2%, respectively. This difference further validated the fact that Span 20 could effectively destabilize the emulsion and improve oil recovery during extraction of walnut. Fig. 5.

- Does span 20 increase oil yield?

- The obtained high oil yield of Span 20 was mainly attributed to its stronger adsorption than protein at the interface and slight oil solubility at acidic pH. Span 20 significantly improved oil yield by allowing the release of oil and decreasing the emulsion fraction, without evident change in the walnut protein.