Vegetable oil extraction machine manufacturer supplies

- Usage:

- palm oill Production

- Type:

- Cold & Hot Pressing Machine, Continuous

- Automatic Grade:

- Automatic

- Production Capacity:

- 100-4000TPD

- Voltage:

- 220V / 380V / 440V

- Power(W):

- 30KW

- Dimension(L*W*H):

- 1200*2800*1200mm

- Weight:

- 1200 Tons

- Certification:

- CE/ ISO/ BV

- After-sales Service Provided:

- Engineers available to service machinery overseas

- solvent consumption:

- 1.5Kg/Ton materials

- Oil Color:

- Yellow

- Oil getting method:

- pressing/extraction

- Heating way:

- steam

- Advantage:

- save water resource

- Bleaching earth consumption:

- 5~50Kg/T oil

- Steam consumption:

- very low

- decolor function:

- to get good color

- deodor function:

- remove the bad smell

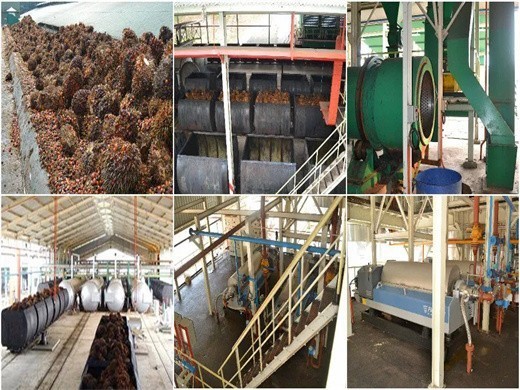

Vegetable oil extraction machine manufacturer supplies high quality mature technology cooking oil processing machine and edible oil refinery plant with factory price,which can produce soybean oil, Palm Oil, groundnut oil, palm oil, etc.

a leader manufacturer of palm oil machine, here you can see palm oil refinery machine detials, palm oil extraction machine installation information,palm kernel oil refinery line, and project reports of crude palm oil refinery machine,palm oil mill plant etc.

palm kernel oil extraction machine, palm kernel oil

A wide variety of palm kernel oil extraction machine options are available to you, There are 439 suppliers who sells palm kernel oil extraction machine, mainly located in Asia. The top countries of supplier is China, from which the percentage of palm kernel oil extraction machine supply is 100% respectively.

How To Start Palm Kernel Oil Extraction Business In Nigeria

The Analysis Of Palm Kernel Oil Extraction Business. PKN – Palm Kernel Nut. The is the nut you get when a palm kernel’s hard shell is broken. That’s the nut where the oil we are talking about is extracted from. PKO – Palm Kernel Oil. This is the actual oil that is being extracted from palm kernel nuts, the actual product or one of the

Oil Extraction Machine at Best Price in Nigeria

Find here online price details of companies selling Oil Extraction Machine. Get info of suppliers, manufacturers, exporters, traders of Oil Extraction Machine for buying in Nigeria.

5. PALM KERNEL OIL EXTRACTION

The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying. The nut processing and oil extraction is undertaken in the dry season when the pressure to obtain raw materials has subsided. The traditional palm oil processing starts with the shelling of the palm nuts.

Oil Extraction Machines - Industrial Oil Press Manufacturer

Our Company is a manufacture, supplier and exporter of Oil Expeller machine which is specially designed to be used for Palm Kernel Oil Extraction. This machine can crush Palm Kernel. Moreover it can crush ground nut, linseeds, palm, palm kernels, seeds, castor, neem, sun flower seeds etc.

Oil Expeller Machine, Oil Processing Plant, Cooking Oil

Yongsheng is specialized in producing grain and oil processing machinery and equipment in China. Such as Oil Expeller Machine, Oil Processing Plant, Cooking Oil Preliminary Pressing Machine, Oil Mill, Corn oil processing Line, Vegetable Oil Solvent Extraction Plant etc.

Oil Extraction Machines - Industrial Oil Press Manufacturer

Our Company is a manufacture, supplier and exporter of Oil Expeller machine which is specially designed to be used for Palm Kernel Oil Extraction. This machine can crush Palm Kernel. Moreover it can crush ground nut, linseeds, palm, palm kernels, seeds, castor, neem, sun flower seeds etc.

Groundnut Oil Extraction Machine Prices in Nigeria (2025)

OIL MACHINE Vegetable Oil Refinery Equipment/ Groundnut Oil Extraction and Refine Machine/Palm Kernel Oil Refine and Processing Machine === N600,000 – N1,000,000 The producers of this one, Oil Machine, are regarded as the best edible oil refinery machinery supplier from China.

High quality palm oil production companies in Kenya

Advance High quality palm oil production companies in Kenya is your source for quality Best supplier in China oil processing equipment and Pillow Block Keyword String accessories. shop online delivery Oil Expeller, Oil Press and Oil Refinery Machine Supplier or pick up in one of our 10000 .

Palm Oil Processing Machine China Manufacturer

Structure of Palm Oil Processing Machine. Oil Expeller with Filter Machine has three main components . 1. Oil press section . 2. Filter control section . 3. Vacuum filter section . Dingzhou Yongsheng Grain and Oil Machinery is the Professional supplier of soybean oil press machine, Vegetable Oil Machinery and Oil Plant Project.

- What is a palm kernel oil extraction machine?

- Palm Kernel Oil Extraction Machine Type: Palm Kernel Oil Extraction Processing material: Palm Kernel Capacity: 200-3000T/D Palm Kernel Oil Extraction Equipment: Crusher, Dryer, Oil Expeller Application: High Efficiency Crude Oil Pressing & Extracting From Palm Kernel With Low Oil Residual … Processing material: Palm Kernel Capacity: 200-3000T/D

- Which equipment should be used for palm kernel oil extraction?

- Palm Kernel Oil Extraction Equipment: Crusher, Dryer, Oil Expeller Solvent extraction plant is recommended for large palm kernel oil mill with high capacity. However, For the purposes of small-scale operations it is sufficient to mention the solvent extraction process is an alternative for high capacity mills.

- How is palm oil extracted?

- Periodically, the shells are scooped out of the bath and discarded. The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil.

- How does a palm kernel oilcake work?

- The expelled kernel oil flows through the slots distributed over the barrel circumference. The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield.