Shaftless thresher for palm oil production line_palm oil

- Usage:

- Palm oil

- Type:

- Cold & Hot Pressing Machine, Palm oil machinery

- Automatic Grade:

- Automatic

- Production Capacity:

- 100TPD Palm oil machinery

- Voltage:

- 380V

- Certification:

- ISO9001

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Material:

- Stainless and Carbonless Steel

- Raw Material:

- Vegetable Oil Suitable for Palm Kernel,Palm

- Pretreatment Process:

- Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Cooking Oil Machinery Process:

- Pre-treatment,Solvent Extraction,Refining

- Refining Process:

- Degumming,Deacidification,Deordorization,Decoloration,etc

- Solvent Extraction Process:

- DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Process Capacity:

- 30-500TPD

- Service:

- Engineer Abroad Erection

- Packing:

- Frame and Container

Small scale palm fruit thresher machine. The working principle of palm fruit thresher machine: Small scale palm fruit thresher machine working principle. Firstly,palm fruits accounts for about 60% of whole palm fruit bunch,due to palm oil is extracted from palm fruits, the first step is to threshing palm fruit bunch and get palm fruits.

Palm oil processing machine. This article mainly introduces crude palm oil processing process, hoping to answer your questions about what machine needed in palm oi processing plant.The entire palm oil processing process is a complex process which includes palm fruit reception setion,paln fruit sterilizing section,palm fruit threshing section,palm fruit digesting & pressing section and palm

Sterilization Station_palm oil processing machine,edible

Processing flow of palm fruit sterilization station during palm oil processing machine: Rail car brings raw material from reception station into the palm fruit sterilization station. Open steam system to make high temperature sterilization to kill the yeast in raw material, destroys esterase activity, then send to the next station of threshing

Palm Oil Pressing Station Palm Oil Mill Machine Leading

The traditional palm oil processing method is different with modern palm oil processing method. The traditional palm oil processing method is as follows: After harvesting, people usually separate palm fruit from bunches manually. And then use hot water to make the palm fruit soften and make it become more easier to press oil.

Palm fruit sterilization station Palm oil extraction machine

Processing flow of palm fruit sterilization station during palm oil processing machine: Rail car brings raw material from reception station into the palm fruit sterilization station. Open steam system to make high temperature sterilization to kill the yeast in raw material, destroys esterase activity, then send to the next station of threshing

Wet Type palm oil extraction plant

After threshing process, we will get palm fruit and empty palm fruit bunches ( EFB ). Then, the separated palm fruit will be transported to the palm oil pressing station to be squeezed. The empty palm fruit bunches will be transported to the boiler station to be used as biomass fuel, or be transported to the palm plantation as a nice fertilizer.

Palm Bunch Sterilization Station Palm Oil Mill Machine

Processing flow of palm fruit sterilization station during palm oil processing machine: Rail car brings raw material from reception station into the palm fruit sterilization station. Open steam system to make high temperature sterilization to kill the yeast in raw material, destroys esterase activity, then send to the next station of threshing

Threshing Station NoakMech

Small scale palm fruit thresher machine. The working principle of palm fruit thresher machine: Small scale palm fruit thresher machine working principle. Firstly,palm fruits accounts for about 60% of whole palm fruit bunch,due to palm oil is extracted from palm fruits, the first step is to threshing palm fruit bunch and get palm fruits.

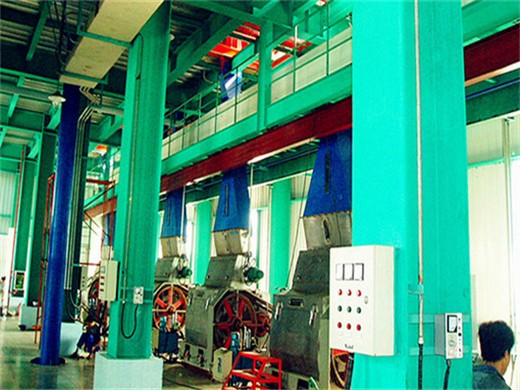

Threshing Station_palm oil processing machine,edible oil

Threshing station uses strong vibration to make separation of palm fruit from palm bunches. Raw materials after sterilization are sent to bucket elevator through damp car, and elevated into threshing machine. Palm fruit separates from bunches, sent to next section elevator through screw conveyor.

The Corn And Energy Price Link Could Tighten As U.S. Election Looms – Advanced BioFuels USA

About Us How to Use This Site Our Board Mission Statement Philosophy Our Staff and Finances Make A Difference Wish List Sponsors Volunteer Job Openings Sign up for

13 tonnes per day copra oil expeller in burundi

13 Tonnes Per Day Automatic Seed Crushing Oil Expeller. Manufacturer of 13 Tonnes Per Day Automatic Seed Crushing Oil Expeller- Large Wheat Flour Processing Plant, Copra palm oil Mill Machinery, Automatic Small palm oil Mill Plant and palm oil Mill Machinery offered by Oil Expeller, Oil Press and Oil Refinery Machine Supplier

dry cleaning machine kenya, dry cleaning machine kenya

New arrival portable high pressure water jet mobile service 8KW steam petrol car wash machine us in kenya and the price US $750.00 - $950.00 / Set